Putting the “bling” on your product is important. Metal work is one of our core competencies at I2V. We specialize in machining, forming as well as molding of various metals. The metals we work with include aluminum, stainless steel, zinc as well as different metal composites. For one-of-a-kind modeling, our metal crafters have the skills to bring a piece of metal to life, paying extra attention to detail and setting a high standard for accuracy. The best of all, our metal work costs a lot less than most prototype house.

Aluminum Machining

Aluminum Chroming | Knurling | Polishing

Stainless Steel Forming

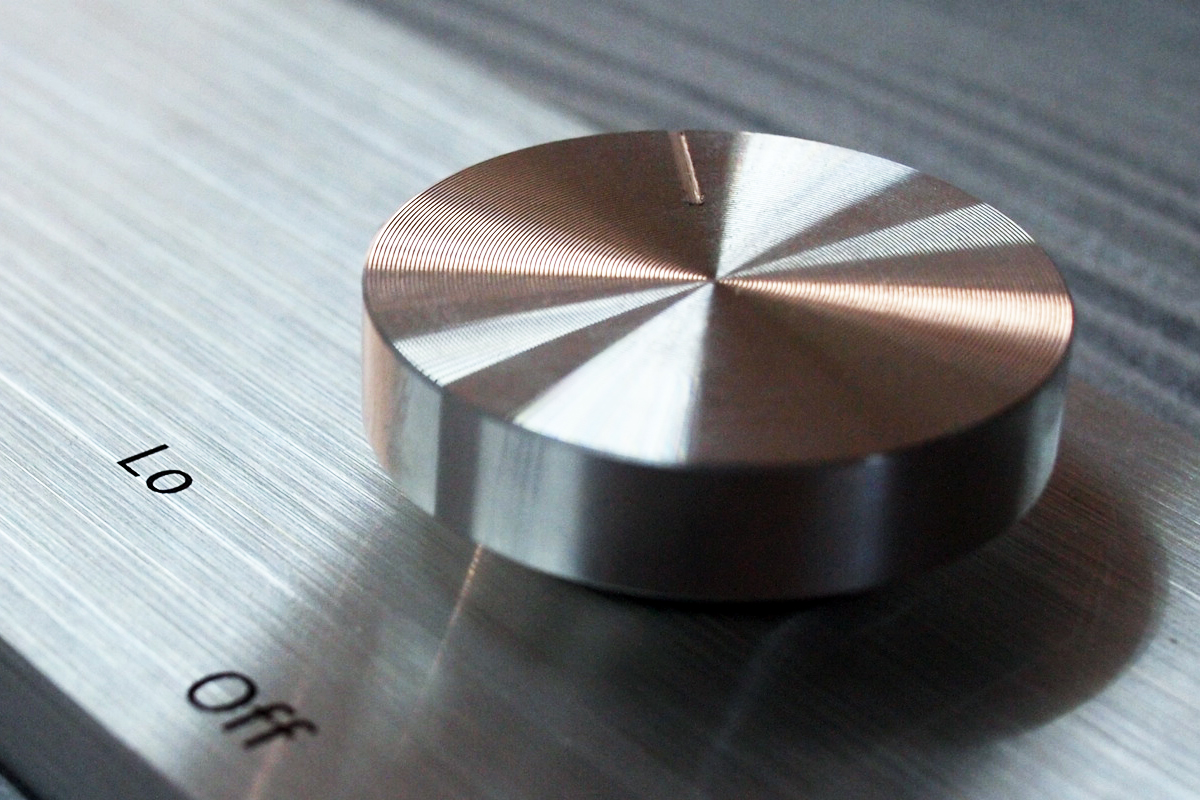

Radial Brushed Knob

Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process. The many processes that have this common theme, controlled material removal, are today collectively known as subtractive manufacturing, in distinction from processes of controlled material addition, which are known as additive manufacturing. Exactly what the “controlled” part of the definition implies can vary, but it almost always implies the use of machine tools (in addition to just power tools and hand tools).

Metal forming, is the metalworking process of fashioning metal parts and objects through mechanical deformation; the workpiece is reshaped without adding or removing material, and its mass remains unchanged.[1] Forming operates on the materials science principle of plastic deformation, where the physical shape of a material is permanently deformed.