Good prototyping is when artistry meets technology. When KitchenAid asked us to make a dozen of their premium water kettles in high-fidelity models for the National Houseware Show, we were confident that our model crafters can deliver a suite of stunning models that will meet the client’s expectation. As any projects, we started with designer CAD drawing and quickly went from digital to physical in about 2 weeks. The body was milled from ABS. The handle and lid was constructed out of aluminum. We put in light-up LEDs that represents the user interface when the product is in use. Here you will see a series of photographs we sent to our client while the model is being constructed so the client can track the progress of the model build.

3D CAD Translation

ABS Polishing before Painting

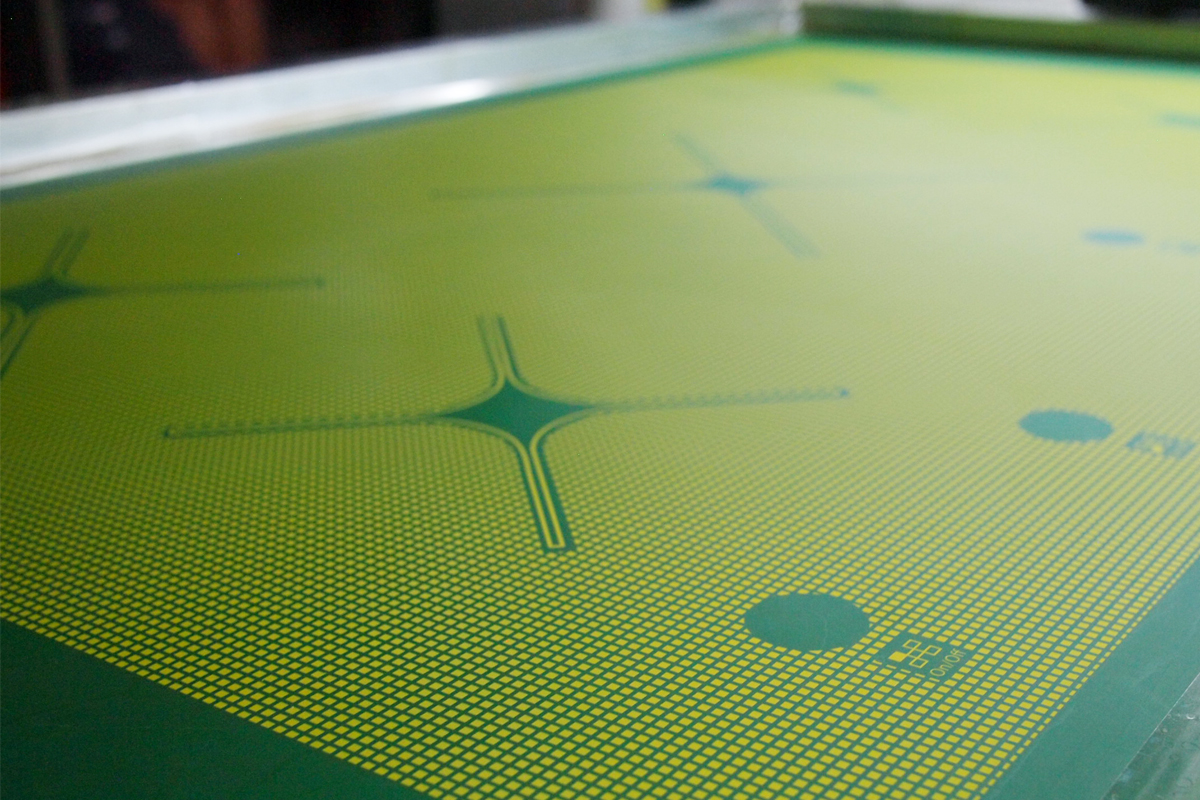

Light-up User Interface

UV Coated Painting and Pearl Metallic Painting

Model VS. Production Comparison

Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process. The many processes that have this common theme, controlled material removal, are today collectively known as subtractive manufacturing, in distinction from processes of controlled material addition, which are known as additive manufacturing. Exactly what the “controlled” part of the definition implies can vary, but it almost always implies the use of machine tools (in addition to just power tools and hand tools).

Metal forming, is the metalworking process of fashioning metal parts and objects through mechanical deformation; the workpiece is reshaped without adding or removing material, and its mass remains unchanged.[1] Forming operates on the materials science principle of plastic deformation, where the physical shape of a material is permanently deformed.